1/6ページ

Download(2.1Mb)

Movie

Document Information

| Document Title | <U.S.A>IGM Series |

|---|---|

| Document Type | Product Catalog |

| File size | 2.1Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page1

IGM DEC 10_IGM REV O6 4 1/13/17 11:40 AM Page 2

1

1. Oil Mist Unit (standard on all models)

2. Coolant Systems (optional) with

Paper Filter with Paper Filter &

Magnetic Separator

IGM Standard Accessories 3. Spindles (optional) IGM-2MB & IGM-15NCIII have endless belt driven

spindles (right). IGM-15NCIII/2 has a

high frequency type spindle (left).

10,000 /15,000/20,000

30,000 /40,000 /60,000 available.

If you need to grind single- See specification chart for details.

step IDs in high volume and are 4. Single Point Dresser with Diamond

looking for the ultimate in 2 3 Tool (standard on IGM-2MB)

throughput and productivity, you 5. Single Point Forming Dresser with

need the Okamoto IGM-2MB. Diamond Tool (optional on IGM-15NCIII

& IGM-15NIII/C2)

This workhorse features a

standard air chuck actuator, a 6. 2-Point Swing Type Dresser with Diamond Tool (standard on IGM-15NCIII/2)

heavy-duty workhead with both 4

7. Radius Dresser (optional on IGM-15NCIII)

angular contact and ball bearings,

8. Rotary Dresser (optional on IGM-15NCIII)

and rugged construction for both 7

X and Z positioning accuracy. 9. Oil Chill Unit (standard on IGM-15NCIII/2)5 6

A single point dresser insures 10.Power Chuck (optional)

close tolerance production part 11.Collet Chuck (optional)

after part. 12.Specialty Chucks (optional - contact

With spindle choices of Okamoto for types & models)

10,000 to 60,000 rpm available 13.Run Light available on all models

and the ability to change spindles

in just a few minutes, you can

optimize grinding wheel surface Not Pictured

speed resulting in better micro-

8 Fanuc 0i-Td Control (standard on IGM-15NCIIIfinishes, closer tolerances, and & IGM-15NCIII/2)

longer wheel life. The Okamoto Necessary Tools & Tool Box (standard on all

IGM-2MB provides flexibility, models)

accuracy, and greater productivity Grinding Control - Front Sliding Splashguard (standard on all

over its generous 1/4 inch to 8 Start & Finish Size models)

inch diameter range. Infeed - Rough/Medium/Fine Leveling Bolts & Pads (standard on all models)Dressing Data - Infeed Amount,

Your operators don’t need experience with Dressing Speed, Number of Dresses, 10 Wheel Spindle Speed Meters

CNC programming to get the most from the (standard on IGM-15NCIII & IGM-15NCIII/2) Spark-Out

Okamoto IGM-2MB! With its easy-to-learn, Wheel Spindle Load Meters (standard on all

models)

easy-to-use MDI control, operators can

effortlessly position the spindle and workpiece Work Spindle Inverter (standard on all models)

to teach the rapid advance, dress, start grind and Wheel Spindle Inverter (standard on IGM-15NCIII & IGM-15NCIII/2)

end grind positions. Dressing cycles can be 9

Workhead Speed Meter (standard on all

programmed to compensate for grinding wheel models)

breakdown and loading. Operators can easily 11 12 13 Dress Coolant Unit (standard on NC models)

adjust the grinding diameter by using the

Work Light

manual pulse generator control. (standard on IGM-15NCIII & IGM-15NCIII/2,

optional on IGM-2MB)

In-Process Gauging (optional on all models)

Internal Grinding Machines / IGM Series

Position Control - Okamoto Corporation

Touch & Teach for Table Stroke, Emerging Abrasives Technology 370 Corporate Woods Parkway, Vernon Hills, IL 60061 USA

Dresser Position, Coolant On/Off Tel: (847) 235-3500 Fax: (847) 235-3274

www.okamotocorp.com

PRINTED IN U.S.A. 12/13 Rev 1 5M

Page2

IGM DEC 10_IGM REV O6 4 1/13/17 11:39 AM Page 1

IGM The Series Specifications C

Program & Tool Storage

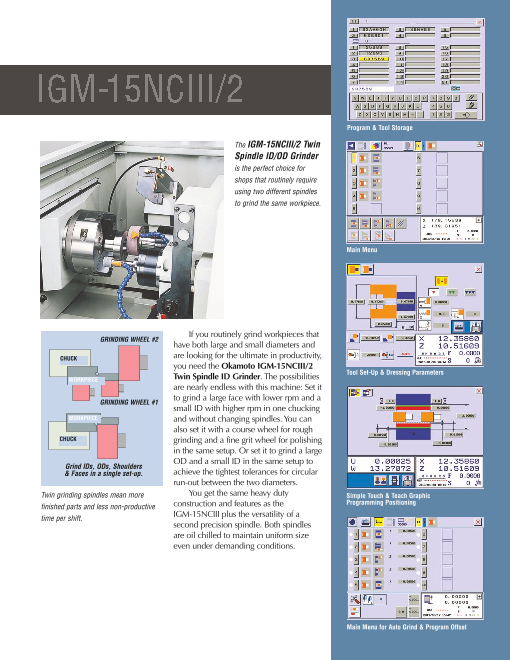

The Okamoto IGM-15NCIII has The IGM-15NCIII/2 Twin B*

the rigidity, power and long-term ASpindle ID/OD Grinder

precision for demanding high-volume A B Cis the perfect choice for

production runs, yet provides quick, IGM-2MB 96" 54" 69"

shops that routinely require

easy set-up and changeover for small IGM-15NCIII 100" 89" 67"

lot runs. With its versatile using two different spindles IGM-15NCIII/2 116" 101" 70"

Fanuc 0i-Td controller, you have the to grind the same workpiece.

*IGM-15NCIII & IGM-15NCIII/2 have pendant mounted CNCs.

choice of easy-to-learn yet powerful

conversational programming or

universal G & M code programming. IGM-2MB IGM-15NCIII IGM-15NCIII/2

Shops that are new to CNC Main Menu CAPACITY

programming appreciate the Internal Diameter to be Ground: 0.24" ~ 8" 0.24" ~ 6" / 8" 0.24" ~ 4" If one spindle - 0.24" ~ 6"

IGM-15NCIII’s teach mode and ability Maximum Grinding Stroke: 8" 5" 3.2" If one spindle - 5"

to store 21 different program types to Swing Over Table: 24" 24" 24"

make job changeovers quick and Swing Inside Splash Guard: 14" 10"

efficient. You can even generate WORKHEAD

multi-type programs that include taper Workhead Speed: 50 ~ 1,700 rpm 100 ~ 850 rpm 100 ~ 850 rpm

and contour grinding as an option. Swivel: -5 ~ +30 deg -5 ~ +15 deg -5 ~ +15 deg

Maximum Crossfeed: 9" N/A N/A

10,000, 15,000, 20,000, 30,000, If you routinely grind workpieces that

GRINDING WHEEL #2 Minimum Feed Increment (Diameter): 0.00001" N/A N/A

40,000 and 60,000 rpm spindles are have both large and small diameters and Automatic Feed Range: 0.004 ~ 0.16 ipm N/A N/A

a vailable, allowing you to optimize CHUCK are looking for the ultimate in productivity, Rapid Feedrate: 10 ipm N/A N/A

grinding wheel surface speeds for any diameter within the you need the Okamoto IGM-15NCIII/2 WHEELHEAD

machines 1/4 inch to 6 inch diameter Twin Spindle ID Grinder. The possibilities Tool Set-Up & Dressing ParametersWORKPIECE Maximum Crossfeed (X- Axis): 1.2" 6.7" 12"

range. Changing spindles is easy. Grinding Wheel Motor are nearly endless with this machine: Set it Feedrate: N/A 0.001 ~ 400 ipm 0.001 ~ 200 ipm

Belt Initial DressingJust release the drive belt to grind a large face with lower rpm and a Rapid Feedrate: 1.8 ipm 400" ipm 200" ipm

GRINDING WHEEL #1

tension and remove two small ID with higher rpm in one chucking Minimum Increment: 0.0001" 0.00001" dia 0.00001" dia

bolts. Swap the spindle Grinding Wheel WORKPIECE and without changing spindles. You can Lubrication: Oil Mist Oil Mist Oil Mist & Oil Cooling

Spindle Taper Grinding Contour Grinding

utilizing Standard Spindle: Option Option 10,000 & 30,000 rpmassemblies, replace the also set it with a course wheel for rough

simultaneous X & Z Optional Wheel Spindles: 10,000/15,000/20,000 10,000/15,000/20,000 10,000 / 20,000 / 30,000

bolts and engage the belt movements Face Dressing CHUCK grinding and a fine grit wheel for polishingAutomatic Spring Tension 30,000/40,000/60,000 rpm 30,000/40,000/60,000 rpm 40,000 / 60,000 rpm

tension. It only takes a few in the same setup. Or set it to grind a large TABLE

minutes to ready the IGM-15NCIII for its next assignment. With the ability to program dressing intervals and OD and a small ID in the same setup to Maximum Longitudinal Travel: 20" 20" 20"

Grind IDs, ODs, Shoulders

Accuracy? Longevity? The IGM-15NCIII delivers both. coolant at the dresser, you can be assured that & Faces in a single set-up. achieve the tightest tolerances for circular Table Speed: 4 ~ 590 ipm 0.001 ~ 400 ipm 0.001 ~ 400 ipm

The grinding spindles are positioned on high precision linear run-out between the two diameters. Minimum Increment (Z- Axis): 0.0001" 0.00001" 0.00001" you'll hold tighter tolerances and better micro- Rapid Feedrate: 590 ipm 400 ipm 400 ipm

guideways mounted with the work spindle to the tough and Twin grinding spindles mean more You get the same heavy duty Simple Touch & Teach Graphic Manual Pulse Handwheel Graduations: 0.0001", 0.0005", 0.0100", 0.00100", 0.0100", 0.00100",

stable meehanite cast base. You can position the grinding finished parts and less non-productive construction and features as the Programming Positioning 0.005", 0.01" 0.00010", 0.00001" 0.00010", 0.00001"

spindle in 10 millionth increments. With your valuable time per shift. IGM-15NCIII plus the versatility of a MOTORS

experience and the IGM-15NCIII, you’ll be capable of second precision spindle. Both spindles Wheel Spindle: 5 hp / 2P 5 hp / 2P 7.5 hp 2 / 4P High-Speed

holding tighter tolerances, achieve better micro-finishes, are oil chilled to maintain uniform size Frequency Inverter Control

and produce more parts per shift than before. even under demanding conditions. Work Spindle: 2 hp / 4P 2 hp / 4P 2 hp / 4P

Crossfeed (X-Axis): 1 hp 1 hp, AC Servo 1 hp, AC Servo

Longitudinal (Z-Axis): 4 hp 1.2 hp, AC Servo 1.2 hp, AC Servo

FLOOR SPACE

Length x Width x Height: 96" x 54" x 69" 100" x 89" x 67" 116" x 101" x 70"

The IGM-15NCIII features the powerful Fanuc 0i -Td controller WEIGHT

that is easy to learn and use, and flexible enough to tackle Net Weight: 6,160 lbs 5,072 lbs 5,300 lbs

complex grinding cycles quickly and accurately.

Specifications Subject to Change Without Notice.

Main Menu for Auto Grind & Program Offset

Page3

IGM DEC 10_IGM REV O6 4 1/13/17 11:39 AM Page 1

IGM The Series Specifications C

Program & Tool Storage

The Okamoto IGM-15NCIII has The IGM-15NCIII/2 Twin B*

the rigidity, power and long-term ASpindle ID/OD Grinder

precision for demanding high-volume A B Cis the perfect choice for

production runs, yet provides quick, IGM-2MB 96" 54" 69"

shops that routinely require

easy set-up and changeover for small IGM-15NCIII 100" 89" 67"

lot runs. With its versatile using two different spindles IGM-15NCIII/2 116" 101" 70"

Fanuc 0i-Td controller, you have the to grind the same workpiece.

*IGM-15NCIII & IGM-15NCIII/2 have pendant mounted CNCs.

choice of easy-to-learn yet powerful

conversational programming or

universal G & M code programming. IGM-2MB IGM-15NCIII IGM-15NCIII/2

Shops that are new to CNC Main Menu CAPACITY

programming appreciate the Internal Diameter to be Ground: 0.24" ~ 8" 0.24" ~ 6" / 8" 0.24" ~ 4" If one spindle - 0.24" ~ 6"

IGM-15NCIII’s teach mode and ability Maximum Grinding Stroke: 8" 5" 3.2" If one spindle - 5"

to store 21 different program types to Swing Over Table: 24" 24" 24"

make job changeovers quick and Swing Inside Splash Guard: 14" 10"

efficient. You can even generate WORKHEAD

multi-type programs that include taper Workhead Speed: 50 ~ 1,700 rpm 100 ~ 850 rpm 100 ~ 850 rpm

and contour grinding as an option. Swivel: -5 ~ +30 deg -5 ~ +15 deg -5 ~ +15 deg

Maximum Crossfeed: 9" N/A N/A

10,000, 15,000, 20,000, 30,000, If you routinely grind workpieces that

GRINDING WHEEL #2 Minimum Feed Increment (Diameter): 0.00001" N/A N/A

40,000 and 60,000 rpm spindles are have both large and small diameters and Automatic Feed Range: 0.004 ~ 0.16 ipm N/A N/A

a vailable, allowing you to optimize CHUCK are looking for the ultimate in productivity, Rapid Feedrate: 10 ipm N/A N/A

grinding wheel surface speeds for any diameter within the you need the Okamoto IGM-15NCIII/2 WHEELHEAD

machines 1/4 inch to 6 inch diameter Twin Spindle ID Grinder. The possibilities Tool Set-Up & Dressing ParametersWORKPIECE Maximum Crossfeed (X- Axis): 1.2" 6.7" 12"

range. Changing spindles is easy. Grinding Wheel Motor are nearly endless with this machine: Set it Feedrate: N/A 0.001 ~ 400 ipm 0.001 ~ 200 ipm

Belt Initial DressingJust release the drive belt to grind a large face with lower rpm and a Rapid Feedrate: 1.8 ipm 400" ipm 200" ipm

GRINDING WHEEL #1

tension and remove two small ID with higher rpm in one chucking Minimum Increment: 0.0001" 0.00001" dia 0.00001" dia

bolts. Swap the spindle Grinding Wheel WORKPIECE and without changing spindles. You can Lubrication: Oil Mist Oil Mist Oil Mist & Oil Cooling

Spindle Taper Grinding Contour Grinding

utilizing Standard Spindle: Option Option 10,000 & 30,000 rpmassemblies, replace the also set it with a course wheel for rough

simultaneous X & Z Optional Wheel Spindles: 10,000/15,000/20,000 10,000/15,000/20,000 10,000 / 20,000 / 30,000

bolts and engage the belt movements Face Dressing CHUCK grinding and a fine grit wheel for polishingAutomatic Spring Tension 30,000/40,000/60,000 rpm 30,000/40,000/60,000 rpm 40,000 / 60,000 rpm

tension. It only takes a few in the same setup. Or set it to grind a large TABLE

minutes to ready the IGM-15NCIII for its next assignment. With the ability to program dressing intervals and OD and a small ID in the same setup to Maximum Longitudinal Travel: 20" 20" 20"

Grind IDs, ODs, Shoulders

Accuracy? Longevity? The IGM-15NCIII delivers both. coolant at the dresser, you can be assured that & Faces in a single set-up. achieve the tightest tolerances for circular Table Speed: 4 ~ 590 ipm 0.001 ~ 400 ipm 0.001 ~ 400 ipm

The grinding spindles are positioned on high precision linear run-out between the two diameters. Minimum Increment (Z- Axis): 0.0001" 0.00001" 0.00001" you'll hold tighter tolerances and better micro- Rapid Feedrate: 590 ipm 400 ipm 400 ipm

guideways mounted with the work spindle to the tough and Twin grinding spindles mean more You get the same heavy duty Simple Touch & Teach Graphic Manual Pulse Handwheel Graduations: 0.0001", 0.0005", 0.0100", 0.00100", 0.0100", 0.00100",

stable meehanite cast base. You can position the grinding finished parts and less non-productive construction and features as the Programming Positioning 0.005", 0.01" 0.00010", 0.00001" 0.00010", 0.00001"

spindle in 10 millionth increments. With your valuable time per shift. IGM-15NCIII plus the versatility of a MOTORS

experience and the IGM-15NCIII, you’ll be capable of second precision spindle. Both spindles Wheel Spindle: 5 hp / 2P 5 hp / 2P 7.5 hp 2 / 4P High-Speed

holding tighter tolerances, achieve better micro-finishes, are oil chilled to maintain uniform size Frequency Inverter Control

and produce more parts per shift than before. even under demanding conditions. Work Spindle: 2 hp / 4P 2 hp / 4P 2 hp / 4P

Crossfeed (X-Axis): 1 hp 1 hp, AC Servo 1 hp, AC Servo

Longitudinal (Z-Axis): 4 hp 1.2 hp, AC Servo 1.2 hp, AC Servo

FLOOR SPACE

Length x Width x Height: 96" x 54" x 69" 100" x 89" x 67" 116" x 101" x 70"

The IGM-15NCIII features the powerful Fanuc 0i -Td controller WEIGHT

that is easy to learn and use, and flexible enough to tackle Net Weight: 6,160 lbs 5,072 lbs 5,300 lbs

complex grinding cycles quickly and accurately.

Specifications Subject to Change Without Notice.

Main Menu for Auto Grind & Program Offset

Page4

IGM DEC 10_IGM REV O6 4 1/13/17 11:39 AM Page 1

IGM The Series Specifications C

Program & Tool Storage

The Okamoto IGM-15NCIII has The IGM-15NCIII/2 Twin B*

the rigidity, power and long-term ASpindle ID/OD Grinder

precision for demanding high-volume A B Cis the perfect choice for

production runs, yet provides quick, IGM-2MB 96" 54" 69"

shops that routinely require

easy set-up and changeover for small IGM-15NCIII 100" 89" 67"

lot runs. With its versatile using two different spindles IGM-15NCIII/2 116" 101" 70"

Fanuc 0i-Td controller, you have the to grind the same workpiece.

*IGM-15NCIII & IGM-15NCIII/2 have pendant mounted CNCs.

choice of easy-to-learn yet powerful

conversational programming or

universal G & M code programming. IGM-2MB IGM-15NCIII IGM-15NCIII/2

Shops that are new to CNC Main Menu CAPACITY

programming appreciate the Internal Diameter to be Ground: 0.24" ~ 8" 0.24" ~ 6" / 8" 0.24" ~ 4" If one spindle - 0.24" ~ 6"

IGM-15NCIII’s teach mode and ability Maximum Grinding Stroke: 8" 5" 3.2" If one spindle - 5"

to store 21 different program types to Swing Over Table: 24" 24" 24"

make job changeovers quick and Swing Inside Splash Guard: 14" 10"

efficient. You can even generate WORKHEAD

multi-type programs that include taper Workhead Speed: 50 ~ 1,700 rpm 100 ~ 850 rpm 100 ~ 850 rpm

and contour grinding as an option. Swivel: -5 ~ +30 deg -5 ~ +15 deg -5 ~ +15 deg

Maximum Crossfeed: 9" N/A N/A

10,000, 15,000, 20,000, 30,000, If you routinely grind workpieces that

GRINDING WHEEL #2 Minimum Feed Increment (Diameter): 0.00001" N/A N/A

40,000 and 60,000 rpm spindles are have both large and small diameters and Automatic Feed Range: 0.004 ~ 0.16 ipm N/A N/A

a vailable, allowing you to optimize CHUCK are looking for the ultimate in productivity, Rapid Feedrate: 10 ipm N/A N/A

grinding wheel surface speeds for any diameter within the you need the Okamoto IGM-15NCIII/2 WHEELHEAD

machines 1/4 inch to 6 inch diameter Twin Spindle ID Grinder. The possibilities Tool Set-Up & Dressing ParametersWORKPIECE Maximum Crossfeed (X- Axis): 1.2" 6.7" 12"

range. Changing spindles is easy. Grinding Wheel Motor are nearly endless with this machine: Set it Feedrate: N/A 0.001 ~ 400 ipm 0.001 ~ 200 ipm

Belt Initial DressingJust release the drive belt to grind a large face with lower rpm and a Rapid Feedrate: 1.8 ipm 400" ipm 200" ipm

GRINDING WHEEL #1

tension and remove two small ID with higher rpm in one chucking Minimum Increment: 0.0001" 0.00001" dia 0.00001" dia

bolts. Swap the spindle Grinding Wheel WORKPIECE and without changing spindles. You can Lubrication: Oil Mist Oil Mist Oil Mist & Oil Cooling

Spindle Taper Grinding Contour Grinding

utilizing Standard Spindle: Option Option 10,000 & 30,000 rpmassemblies, replace the also set it with a course wheel for rough

simultaneous X & Z Optional Wheel Spindles: 10,000/15,000/20,000 10,000/15,000/20,000 10,000 / 20,000 / 30,000

bolts and engage the belt movements Face Dressing CHUCK grinding and a fine grit wheel for polishingAutomatic Spring Tension 30,000/40,000/60,000 rpm 30,000/40,000/60,000 rpm 40,000 / 60,000 rpm

tension. It only takes a few in the same setup. Or set it to grind a large TABLE

minutes to ready the IGM-15NCIII for its next assignment. With the ability to program dressing intervals and OD and a small ID in the same setup to Maximum Longitudinal Travel: 20" 20" 20"

Grind IDs, ODs, Shoulders

Accuracy? Longevity? The IGM-15NCIII delivers both. coolant at the dresser, you can be assured that & Faces in a single set-up. achieve the tightest tolerances for circular Table Speed: 4 ~ 590 ipm 0.001 ~ 400 ipm 0.001 ~ 400 ipm

The grinding spindles are positioned on high precision linear run-out between the two diameters. Minimum Increment (Z- Axis): 0.0001" 0.00001" 0.00001" you'll hold tighter tolerances and better micro- Rapid Feedrate: 590 ipm 400 ipm 400 ipm

guideways mounted with the work spindle to the tough and Twin grinding spindles mean more You get the same heavy duty Simple Touch & Teach Graphic Manual Pulse Handwheel Graduations: 0.0001", 0.0005", 0.0100", 0.00100", 0.0100", 0.00100",

stable meehanite cast base. You can position the grinding finished parts and less non-productive construction and features as the Programming Positioning 0.005", 0.01" 0.00010", 0.00001" 0.00010", 0.00001"

spindle in 10 millionth increments. With your valuable time per shift. IGM-15NCIII plus the versatility of a MOTORS

experience and the IGM-15NCIII, you’ll be capable of second precision spindle. Both spindles Wheel Spindle: 5 hp / 2P 5 hp / 2P 7.5 hp 2 / 4P High-Speed

holding tighter tolerances, achieve better micro-finishes, are oil chilled to maintain uniform size Frequency Inverter Control

and produce more parts per shift than before. even under demanding conditions. Work Spindle: 2 hp / 4P 2 hp / 4P 2 hp / 4P

Crossfeed (X-Axis): 1 hp 1 hp, AC Servo 1 hp, AC Servo

Longitudinal (Z-Axis): 4 hp 1.2 hp, AC Servo 1.2 hp, AC Servo

FLOOR SPACE

Length x Width x Height: 96" x 54" x 69" 100" x 89" x 67" 116" x 101" x 70"

The IGM-15NCIII features the powerful Fanuc 0i -Td controller WEIGHT

that is easy to learn and use, and flexible enough to tackle Net Weight: 6,160 lbs 5,072 lbs 5,300 lbs

complex grinding cycles quickly and accurately.

Specifications Subject to Change Without Notice.

Main Menu for Auto Grind & Program Offset

Page5

IGM DEC 10_IGM REV O6 4 1/13/17 11:40 AM Page 2

1

1. Oil Mist Unit (standard on all models)

2. Coolant Systems (optional) with

Paper Filter with Paper Filter &

Magnetic Separator

IGM Standard Accessories 3. Spindles (optional) IGM-2MB & IGM-15NCIII have endless belt driven

spindles (right). IGM-15NCIII/2 has a

high frequency type spindle (left).

10,000 /15,000/20,000

30,000 /40,000 /60,000 available.

If you need to grind single- See specification chart for details.

step IDs in high volume and are 4. Single Point Dresser with Diamond

looking for the ultimate in 2 3 Tool (standard on IGM-2MB)

throughput and productivity, you 5. Single Point Forming Dresser with

need the Okamoto IGM-2MB. Diamond Tool (optional on IGM-15NCIII

& IGM-15NIII/C2)

This workhorse features a

standard air chuck actuator, a 6. 2-Point Swing Type Dresser with Diamond Tool (standard on IGM-15NCIII/2)

heavy-duty workhead with both 4

7. Radius Dresser (optional on IGM-15NCIII)

angular contact and ball bearings,

8. Rotary Dresser (optional on IGM-15NCIII)

and rugged construction for both 7

X and Z positioning accuracy. 9. Oil Chill Unit (standard on IGM-15NCIII/2)5 6

A single point dresser insures 10.Power Chuck (optional)

close tolerance production part 11.Collet Chuck (optional)

after part. 12.Specialty Chucks (optional - contact

With spindle choices of Okamoto for types & models)

10,000 to 60,000 rpm available 13.Run Light available on all models

and the ability to change spindles

in just a few minutes, you can

optimize grinding wheel surface Not Pictured

speed resulting in better micro-

8 Fanuc 0i-Td Control (standard on IGM-15NCIIIfinishes, closer tolerances, and & IGM-15NCIII/2)

longer wheel life. The Okamoto Necessary Tools & Tool Box (standard on all

IGM-2MB provides flexibility, models)

accuracy, and greater productivity Grinding Control - Front Sliding Splashguard (standard on all

over its generous 1/4 inch to 8 Start & Finish Size models)

inch diameter range. Infeed - Rough/Medium/Fine Leveling Bolts & Pads (standard on all models)Dressing Data - Infeed Amount,

Your operators don’t need experience with Dressing Speed, Number of Dresses, 10 Wheel Spindle Speed Meters

CNC programming to get the most from the (standard on IGM-15NCIII & IGM-15NCIII/2) Spark-Out

Okamoto IGM-2MB! With its easy-to-learn, Wheel Spindle Load Meters (standard on all

models)

easy-to-use MDI control, operators can

effortlessly position the spindle and workpiece Work Spindle Inverter (standard on all models)

to teach the rapid advance, dress, start grind and Wheel Spindle Inverter (standard on IGM-15NCIII & IGM-15NCIII/2)

end grind positions. Dressing cycles can be 9

Workhead Speed Meter (standard on all

programmed to compensate for grinding wheel models)

breakdown and loading. Operators can easily 11 12 13 Dress Coolant Unit (standard on NC models)

adjust the grinding diameter by using the

Work Light

manual pulse generator control. (standard on IGM-15NCIII & IGM-15NCIII/2,

optional on IGM-2MB)

In-Process Gauging (optional on all models)

Internal Grinding Machines / IGM Series

Position Control - Okamoto Corporation

Touch & Teach for Table Stroke, Emerging Abrasives Technology 370 Corporate Woods Parkway, Vernon Hills, IL 60061 USA

Dresser Position, Coolant On/Off Tel: (847) 235-3500 Fax: (847) 235-3274

www.okamotocorp.com

PRINTED IN U.S.A. 12/13 Rev 1 5M

Page6

IGM DEC 10_IGM REV O6 4 1/13/17 11:40 AM Page 2

1

1. Oil Mist Unit (standard on all models)

2. Coolant Systems (optional) with

Paper Filter with Paper Filter &

Magnetic Separator

IGM Standard Accessories 3. Spindles (optional) IGM-2MB & IGM-15NCIII have endless belt driven

spindles (right). IGM-15NCIII/2 has a

high frequency type spindle (left).

10,000 /15,000/20,000

30,000 /40,000 /60,000 available.

If you need to grind single- See specification chart for details.

step IDs in high volume and are 4. Single Point Dresser with Diamond

looking for the ultimate in 2 3 Tool (standard on IGM-2MB)

throughput and productivity, you 5. Single Point Forming Dresser with

need the Okamoto IGM-2MB. Diamond Tool (optional on IGM-15NCIII

& IGM-15NIII/C2)

This workhorse features a

standard air chuck actuator, a 6. 2-Point Swing Type Dresser with Diamond Tool (standard on IGM-15NCIII/2)

heavy-duty workhead with both 4

7. Radius Dresser (optional on IGM-15NCIII)

angular contact and ball bearings,

8. Rotary Dresser (optional on IGM-15NCIII)

and rugged construction for both 7

X and Z positioning accuracy. 9. Oil Chill Unit (standard on IGM-15NCIII/2)5 6

A single point dresser insures 10.Power Chuck (optional)

close tolerance production part 11.Collet Chuck (optional)

after part. 12.Specialty Chucks (optional - contact

With spindle choices of Okamoto for types & models)

10,000 to 60,000 rpm available 13.Run Light available on all models

and the ability to change spindles

in just a few minutes, you can

optimize grinding wheel surface Not Pictured

speed resulting in better micro-

8 Fanuc 0i-Td Control (standard on IGM-15NCIIIfinishes, closer tolerances, and & IGM-15NCIII/2)

longer wheel life. The Okamoto Necessary Tools & Tool Box (standard on all

IGM-2MB provides flexibility, models)

accuracy, and greater productivity Grinding Control - Front Sliding Splashguard (standard on all

over its generous 1/4 inch to 8 Start & Finish Size models)

inch diameter range. Infeed - Rough/Medium/Fine Leveling Bolts & Pads (standard on all models)Dressing Data - Infeed Amount,

Your operators don’t need experience with Dressing Speed, Number of Dresses, 10 Wheel Spindle Speed Meters

CNC programming to get the most from the (standard on IGM-15NCIII & IGM-15NCIII/2) Spark-Out

Okamoto IGM-2MB! With its easy-to-learn, Wheel Spindle Load Meters (standard on all

models)

easy-to-use MDI control, operators can

effortlessly position the spindle and workpiece Work Spindle Inverter (standard on all models)

to teach the rapid advance, dress, start grind and Wheel Spindle Inverter (standard on IGM-15NCIII & IGM-15NCIII/2)

end grind positions. Dressing cycles can be 9

Workhead Speed Meter (standard on all

programmed to compensate for grinding wheel models)

breakdown and loading. Operators can easily 11 12 13 Dress Coolant Unit (standard on NC models)

adjust the grinding diameter by using the

Work Light

manual pulse generator control. (standard on IGM-15NCIII & IGM-15NCIII/2,

optional on IGM-2MB)

In-Process Gauging (optional on all models)

Internal Grinding Machines / IGM Series

Position Control - Okamoto Corporation

Touch & Teach for Table Stroke, Emerging Abrasives Technology 370 Corporate Woods Parkway, Vernon Hills, IL 60061 USA

Dresser Position, Coolant On/Off Tel: (847) 235-3500 Fax: (847) 235-3274

www.okamotocorp.com

PRINTED IN U.S.A. 12/13 Rev 1 5M