1/16ページ

Download(2.3Mb)

Document Information

| Document Title | <U.S.A>PRODUCTS GUIDE |

|---|---|

| Document Type | Product Catalog |

| File size | 2.3Mb |

| Category | |

| Company | OKAMOTO MACHINE TOOL WORKS,LTD (Documents List) |

Documents related to this company

Document Contents

Page2

ACC Series Precision Column Type Surface Grinding Machines

The ACC Series is available with three control options to meet specific grinding

applications. Choose from Automatic, MDI Control (Manual Data Input) or full 2-axis

simultaneous CNC in a wide range of capacities. In all, there are 45 models.

Whether the application is small lot, high-precision parts, or rigorous high-volume

production, these rugged machines provide true precision, long-term reliability and

broad application flexibility.

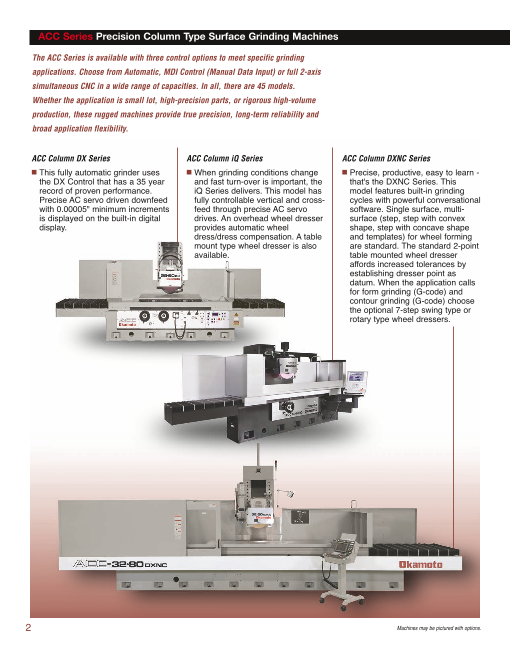

ACC Column DX Series ACC Column iQ Series ACC Column DXNC Series

n This fully automatic grinder uses n When grinding conditions change n Precise, productive, easy to learn -

the DX Control that has a 35 year and fast turn-over is important, the that's the DXNC Series. This

record of proven performance. iQ Series delivers. This model has model features built-in grinding

Precise AC servo driven downfeed fully controllable vertical and cross- cycles with powerful conversational

with 0.00005" minimum increments feed through precise AC servo software. Single surface, multi-

is displayed on the built-in digital drives. An overhead wheel dresser surface (step, step with convex

display. provides automatic wheel shape, step with concave shape

dress/dress compensation. A table and templates) for wheel forming

mount type wheel dresser is also are standard. The standard 2-point

available. table mounted wheel dresser

affords increased tolerances by

establishing dresser point as

datum. When the application calls

for form grinding (G-code) and

contour grinding (G-code) choose

the optional 7-step swing type or

rotary type wheel dressers.

2 Machines may be pictured with options.

Page3

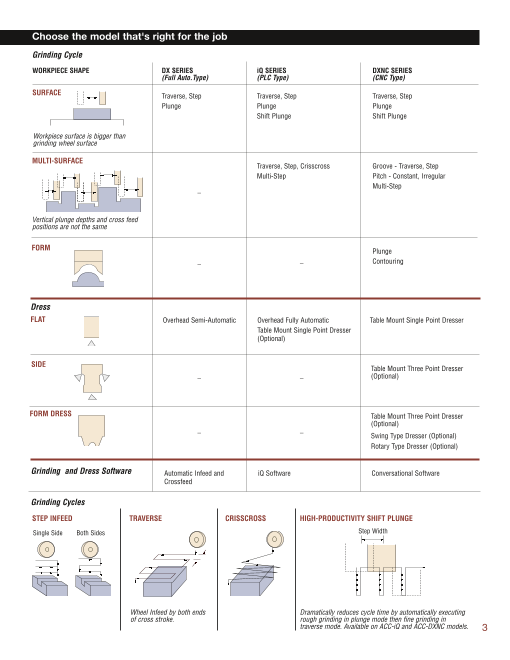

Choose the model that's right for the job

Grinding Cycle

WORKPIECE SHAPE DX SERIES iQ SERIES DXNC SERIES

(Full Auto.Type) (PLC Type) (CNC Type)

S U R F A C E Traverse, Step Traverse, Step Traverse, Step

Plunge Plunge Plunge

Shift Plunge Shift Plunge

Workpiece surface is bigger than

grinding wheel surface

MULTI-SURFACE

Traverse, Step, Crisscross Groove - Traverse, Step

Multi-Step Pitch - Constant, Irregular

_ Multi-Step

Vertical plunge depths and cross feed

positions are not the same

F O R M Plunge

_ _ Contouring

Dress

F L A T Overhead Semi-Automatic Overhead Fully Automatic Table Mount Single Point Dresser

Table Mount Single Point Dresser

(Optional)

SIDE Table Mount Three Point Dresser

_ _ (Optional)

FORM DRESS Table Mount Three Point Dresser

(Optional)

_ _

Swing Type Dresser (Optional)

Rotary Type Dresser (Optional)

G r i n d i n g a n d D r e s s S o f t w a r e Automatic Infeed and iQ Software Conversational Software

Crossfeed

Grinding Cycles

STEP INFEED TRAVERSE CRISSCROSS HIGH-PRODUCTIVITY SHIFT PLUNGE

Single Side Both Sides Step Width

Wheel Infeed by both ends Dramatically reduces cycle time by automatically executing

of cross stroke. rough grinding in plunge mode then fine grinding in

traverse mode. Available on ACC-iQ and ACC-DXNC models. 3

Page4

Superior design and construction for the heaviest grinding applications

Okamoto Column Types design assures superior Rigidity, Accuracy and Reliability -

Work Envelope Access for simplified large work set-up and in-process inspection

Why Column Type Design is Better

The grinding wheel is part of the column assembly, both

move simultaneously. The table travels longitudinally on

the machine bed. Crossfeed is executed by column travel

so chuck/workpiece to operator distance remains

constant. The result is optimum operator convenience,

safety and operation.

COLUMN

GRINDING

HEAD

BED

TABLE

FRAME

Column assembly and table frame

Outstanding infeed accuracy with high rigidity design

GRINDING

SPINDLE

TABLE

FRAME

Over 60 years of grinding machine experience go into At no point during table reciprocation does the chuck

every grinder. Robust cast iron has the thickness and work zone overhang the machine frame. This eliminates

strategically located ribbing to ensure maximum long-term deflection due to weight stresses and assures consistent

rigidity. The wheelhead is fully supported by 6 slideways. accuracy throughout the full grinding stroke.

The column assembly incorporates a unique ventilation

port to evacuate hot air from the column interior resulting The combination of a V-F slideway and hydraulic cylinder

in enhanced thermal stability. provides for stable table movement and speed even withheavy workpieces or slow table speeds.

Okamoto Column Type Surface Grinders are renowned

for their large and heavy workpiece capacities.

4

Page5

Precise heavy grinding conditions demand an

exceptional spindle.

The cartridge type ACC Column OPTION STANDARD

wheel spindle is designed to 4" 3"1" 1"

deliver peak accuracy even under

the heaviest grinding demands.

A specially designed, precision

balanced spindle motor drives ø11.25" ø10.25" 8" ø20"

the spindle through a flexible

coupling that absorbs vibration

while transmitting full horsepower.

An impeller mounted on the motor

shaft expels heat away from the spindle out the column

vents. Bearings are sealed and lubed for life.

Reliable Hydraulic / Lubrication System Optimum Thermal Stability means Optimum Accuracy.

Consistent, dependable lubrication is

the lifeblood of any machine. ACC

Column Grinders utilize a reliable

gravity feed system that provides

critical lubrication to all slideways and

positioning screws.

GRINDING HEAD

SLIDEWAY

SPINDLE

AUTO.TEMP.

CONTROL

HEAT EXCHANGE UNIT

UNIT (Option)

COOLANT TANK

TABLE LONGITUDINAL (Option)

SLIDEWAY The hydraulic units / temperature regulating systems are designed to be

positioned away from the grinding machine. This eliminates the transmission

of accuracy robbing heat and vibration to the machine.

AUTO.TEMP.

HYDRAULIC CONTROL ACC-DX Series: Oil Temperature Regulator standard

UNIT UNIT

(EX: Option) ACC-iQ Series: Oil Temperature Regulator standard. Spindle housing

temperature controlled by hydraulic oil.

SADDLE BED SLIDEWAY

ACC-DXNC Series: Oil Temperature Regulator standard. Spindle housing

temperature controlled by hydraulic oil. If desired, a heat

exchange unit can be connected to grinder's coolant tank.

5

Page6

ACC-DX Series

Machines may be pictured with options.

ACC-DX Models deliver rugged performance, superb precision and long-term

dependability at an affordable price. They utilize Okamoto's exclusive MDI control

system that assures consistent precise infeed. Minimum increment is 0.000050".

Total stroke is also displayed. This easy-to-use control simplifies touch down and

minimizes air cut time.

Optimum Convenience High Precision Simple Operation

The DX Series lets today's The best components make for the Okamoto's DX control system

progressive machinists enjoy the best machine. The combination of a simplifies the grinders’ fully

convenience, flexibility and safety of high resolution AC servo motor and automatic cycle. Coarse grinding,

Okamoto column type design. The fine pitch ballscrew delivers Fine Grinding, Spark-out and

traveling column assures outstanding infeeds of 0.00005". Table Stop are all part of the

unobstructed access to the work Okamoto's LSI Control System machines’ integrated grind cycle.

envelope even with extra-large allows operators to select infeeds Vertical wheelhead positions are

workpieces. Parts loading/unloading from 0.00005" to 0.0025" through always displayed on the vertical

and in-process inspection is also simple switch operation. digital display.

simplified. All handwheels, switches

and control buttons are conveniently

located on the front control panel.

An interlock system during the auto

cycle and protective covers for table

dogs and other machine components

promotes operator safety.

6

Page7

Operation Panel

n9 n10

n6 n8 n11

n2 n4 n5 n7

n1 n3

n12

n1 Table Longitudinal Feed Handwheel n10 Table Start Right Pushbutton n18 Reset Switch

n2 Crossfeed Reversing Limit Selector n11 Table Right End Stop Pushbutton n19 Grinding Mode Selector Switch

n3 Crossfeed Handwheel n12 Grinding Mode Selector Switch n20 Coarse Grinding Infeed Selector Switch

n4 Manual Pulse Generator for Vertical Feed n13 Wheelhead Rapid Traverse Switch n21 Fine Grinding Stock Removal Set up

n5 Crossfeed Direction Control Switch n14 Rapid/Jog Infeed Switch Switch

n6 Crossfeed Speed Adjusting Lever n15 Vertical Positioning Display (during auto n

22 Fine Grinding Infeed Selector Switch

n Wheel Dressing Speed Adjusting Knob mode : Stock removal amount display) n

23 Spark-out Counter Switch (0 - 5 times)

7

and Direction Change Lever n16 Reset Switch

n8 Table Speed Adjusting Lever n17 Crossfeed Positioning Display (Option)

n9 Table Start Left Pushbutton

n15 n16 n20 WORKPIECE SURFACE (GRINDING STARTING POINT)

n13 n21

20n17 n18 n14 n19 COARSE INFEED AMOUNT 4 INTERRUPT BY MPGn22 n23 COARSE STOCK REMOVAL AMOUNT

COARSE GRINDING

COARSE STOCK

REMOVAL AMOUNT

FINE GRINDING

21 FINE STOCK 22 23REMOVAL AMOUNT SPARK OUT

n4 Manual Pulse Generator Self Diagnostic Function

All Column DX models are equipped n12 Grinding Mode Select Switch

with a Vertical Feed Manual Pulse Traverse: Downfeed signal at the Simply press "DGN" key LED aided

Generator as standard. This gives end of each Crossfeed reversal troubleshooting.

the operator necessary mobility for Plunge 1: Downfeed signal at right Stock Removal Set-Up

wheelhead positioning during set-up. end of the table stroke

Fine feed increments of 0.00005" Total stock removal amount is input

and 0.005" per handwheel revolution Plunge 2: Downfeed signal at both and displayed through simple key

enables precise wheel to work ends of the table stroke input. The Fine Grinding Stock

positioning. If desired, an optional Amount Selector Switch enables the

vertical feed handwheel is available operator to switch between Coarse

on all models. and Fine grinding input modes.

7

Page8

ACC-iQ Series

ACC-iQ Models provide all the performance, precision and dependability of the

DX Series plus a new degree in convenience. Their easy-to-use Touch-Screen Interactive

Graphical Software simplifies set-up, change-over and boosts productivity.

ACC-iQ Series Column Grinders use Okamoto’s state-of-the-art iQ Control

Okamoto's “user-friendly” grinding delivers a new degree in

software. This proven software programming simplicity. Simply input

simplifies all phases of the grinding total stock removal, fine stock

operation while giving the operator removal and grinding wheel data -

the “feel” of conventional machine the control then automatically selects

operation. This simple “teach the optimum grinding and dress

function” simplifies vertical sizing conditions.

position, crossfeed point and

dressing position. Vertical and

Cross movement, Automatic

Downfeed (Traverse or Plunge) are

programmable in selected user

increments from 0.00001" to 0.004".

The minimum Crossfeed increment

is 0.00001".

Machines may be pictured with options.

8

Page9

High Performance

iQ Functions

n Powerful Spindle Motor

n Overhead Wheel Dresser

with Automatic Dress

Compensation used for

coarse and fine grinding cycles

n Shift/Plunge Grinding

dramatically reduces cycle times

3-Step Form Set-Up Page 3-Step Convex Form Set-Up Page n iQ’s cycle Time Calculation

Function boosts productivity

n iQ automatically selects

optimum shift amount during

Shift-Plunge cycle for

maximum grinding efficiency

n Standard Spindle Inverter,

Hydraulic Oil Temperature

Regulator and Grinding Head

Oil Circulation assure

continuous optimum accuracy

3-Step Concave Form Set-Up Page Dress Set-Up Page

Grinding Data Screen

MODE SELECTION MENU

Table Stroke Set Up Dress Data Set Up Grinding Data Set Up Multiple Menu Data Preserve

Data Call, Data Edit

Parameter

Datum Set Up (Screen shows Work Surface Datum)

n1 Select for Step Infeed or Crisscross Continuous Infeed

n2 Select for Chuck Surface Datum or Work Surface Datum

3 n3 Set Up Air Cut Amount

n1

n1 Display Current Grinding Wheel Shape

n2 n2 Change Dress Condition During Cycle

n3 Compensation Grinding

n3

Datum Selection

00.0000 00.0000

n1 Coarse Grinding Infeed Amount & Coarse Grinding 00.0000 00.0000

Cross Feed Speed (F-Key) 7 8 9Fine Grinding 00.0000

7 8 9

4 5 6 4 5 6

n2 Fine Grinding Infeed Amount & Inching Key 1 2 3 1 2 30 . 0 .

Cross Feed Speed (F-Key)

3 Work Surface Datum Chuck Surface Datumn Left Side Sparkout (Timer Setup)

Right Side IQ Cycle Time Calculation

9

Page10

ACC-DXNC Series

Machines may be pictured with options.

Various Dressing Units Wheel Forming Tracks

The Single Point Dresser Unit (located

Y table left side) uses Column Crossfeed

and Grinding Wheel vertical movement

Z to generate flat dress or multi-flat

Z grinding.

Y

Table Mount Single Point Dresser Unit

The 3-Point Dresser unit (located table

left side) has a top and 2 side-mounted

diamonds needed to prepare Angle

Dress, Side Dress or Radius Wheel Forms.

Y Y

n For Angle Dress (45 deg. divide)

Z For use wheel OD dress, Angle

Dress (V-shape) form

n For Side Dress (90 deg. divide).

For use wheel OD dress, single

Table Mount 3-Point Dresser Unit (optional) side dress, both side dress form.

The Swing-Type Dresser Unit (located

Y table right side). Dresser arm can be

Y tilted +/- 30 deg., +/- 15 deg. and 0 deg.

to avoid interference between diamond

Z tool and shoulder, and make universal

Z wheel forms with 2-axes simultaneous

control for Cross and Vertical Infeed.

Optional Rotary and Swing Type Dresser

10 (optional)

Page11

Easy operation with Operator Friendly Software

Minimum increment 0.00001" for [Grinding wheel Vertical & Crossfeed feed]

High Efficiency for Setting up time with 78 IPM for Vertical movement, 196 IPM for Cross movement.

High level of consistency to assure high CNC takes on complicated procedures Dress Interruption during Auto Cycle

accuracy tolerances n Easy input sizing or positioning. n Dress button can be pushed at any

n Vertical Feed Slideway for Low Friction Teaching function allows for easy time during auto cycle. Upon dress

Crossfeed Slideway (V-V) position inputs completion, cycle resumes at last n

n Hydraulic Type Counter Balance No position reference needed for start.

grinding datum position.

n

Cylinder Eliminates useless air cuts or start positions. Coarse Grinding Cycle included as

n Oil Cool Type Spindle Housing for standard

Thermal Control

n High Efficiency Shift Plunge grinding

mode for coarse plunge grinding to

fine traverse grinding incorporated in

one easy-to-use cycle

User Friendly Conversational Software

Menu Dressing Menu Selection Grinding Menu Selection Grinding Data - A

Grinding Data - B

Dresser Select Grinding Wheel Data Input Grinding Mode Setup Screen Datum Position Setup

Return to Menu Screen Return to Menu Screen

Structure for Menu Screen

Menu-1 (Dress Position Set-up ) (Dresser Set-up or Select Dresser Unit)

and (Dressing Datum) Set-up.

Menu-2 (Dress Menu Set-up) (Select Wheel Form) (Data for Form) Set-up

(Single Dress) Action

Menu-3 (Grinding Menu Set-up)

User Friendly Conversational Software

MARK: WORK DATUM POSITION

WORK DATUM POSITION Y

Work Form Setup Datum Position Setup

WORK DATUM POSITION Completed Data InputDRESSER

11

Page12

Standard and Optional Accessories to meet any demand

Standard Accessories Optional Accessories

No Items DX iQ DXNC

1 Grinding Wheel O O O Coolant System with Magnetic Dust Separator

2 Wheel Adapter O O O Coolant System with Magnetic Dust Separator and

Paper Filter System

3 Hydraulic Type Over-the-Wheel Dresser O O -

Coolant Temperature Regulator

4 Automatic Dress Compensation Type N/A O O

Electro Magnetic Chuck

5 Table Mount Type Diamond Dresser Tool N/A Option O

Tool with Holder Chuck Controller for Normal Electro-Magnetic Chuck

6 Hand Held Vertical & Cross - O O Electro-Permanent Magnetic Chuck

Manual Pulse Generator Chuck Controller for Electro-Permanent Magnetic Chuck

7 15hp Wheel Spindle Motor O O O Oil Cooling Type Electro Magnetic Chuck

8 Spindle Inverter Option O O Oil Cooling Type Spindle Housing

9 Wheel Guard + Magnet Stand Base O O O Grinding Wheel Balancing Stand with Arbor

10 Splash Cover with Coolant Nozzle & Pipe O O O Balancing Test Arbor

11 Hydraulic Oil Temperature Controller O O O Grinding Wheel Adapter

12 Hydraulic Oil Cool Type Spindle Housing Option O O Grinding Wheel Adapter for Micro Balancer

13 Signal Tower (3-Color Type) Option Option O Micro Balancer System

14 Table Lifting System By Hydraulic System O O O Hydraulic Oil Temperature Regulator

15 Controller System Okamoto Okamoto Fanuc Vertical Spindle Attachment with Dressing Device

16 Graphic Type Conversational Software - O O Grinding Wheel Adapter for Vertical Spindle Unit

17 G-Code Program Capability - - O Frequency Inverter for Wheel Spindle (DX only)

18 Hydraulic Cylinder Type Signal Light (3-Color Type)

Weight Balance System - - O Calendar Timer

19 Leveling Bolts with Plates O O O Table Enclosure

20 Necessary Tools & Tool Box O O O

Coolant System Grinding Wheel Balancing Stand Electro-magnetic Chuck Dynamic Wheel Balancing System

with Arbor

Indexing System Overhead Wheel Dresser Micro Balancer System

Vertical Spindle Attachment

12

Page13

Floor Plans / Weights

20

5.47 5.91

C

D E F

G H

I J

K L

A B

ACC DX SERIES (Dimensions in Inches)

24l48 24l60 28l60 32l80

A 213 216 216 263

B 106 119 125

C 86 94 94

D 33.46 37.4 37.4

E / F 12.99 14.96 16.93

G / H 15.16 17.13 19.09

I / J 11.81 13.78 15.75

K / L 7.87 11.81 11.81

WEIGHT (in Lbs.)

17,200 18,520 23,3 70 26,900

ACC iQ SERIES (Dimensions in Inches)

24l48 24l60 28l60

A 213 216 216

B 142 142 152

C 87 95

D 33.07 37.4

E / F 12.99 14.96

G / H 15.16 17.13

I / J 11.81 13.78

K / L 7.87 11.81

WEIGHT (in Lbs.)

16,760 18,100 22,880

ACC DXNC SERIES (Dimensions in Inches)

24l48 24l60 28l60 32l80

A 229 231 231 263

B 116 126 132

C 125 134 134

D 32.67 36.61 36.61

E / F 13.58 14.96 16.92

G /H 13.19 17.12 19.09

I / J 9.84 13.77 15.74

K / L 7.87 11.81 11.81

WEIGHT (in Lbs.)

17,200 18,520 23,370 26,660

13

Page14

Specifications

MODEL Unit ACC-24l48* ACC-24l60* ACC-28l60* ACC-32l80

CAPACITY

Grinding Capacity (W x L) in. 24 x 48 24 x 60 28 x 60 32 x 120

Max. Movement (W x L) in. 26 x 57 26 x 69 30 x 69 34 x 128

Table Working Surface (W x L) in. 24 x 48 24 x 60 28 x 60 32 x 120

Max. Dist. Under Wheel in. 27.3 (26.5 iQ Models)

Magnetic Chuck Size (W x L x H) in 24 x 47 x 4.3 24 x 59 x 4.3 28 x 59 x 4.3 32 x 118 x 4.3

Table Load Capacity (Incl. Chuck) lbs 5,510 (1,170) 5,260 (1,330) 5,640 (1,700) 6,170 (3,910)

T-Slots (W x No.) in. 0.78 x 3

GRINDING WHEEL

Dimensions (D x W x B) in. 20 x 3 x 8 (20 x 3 x 5 optional)

Speed rpm 1,100 (60Hz)

MOTORS

Grinding Wheel Spindle hp 20 20 (30 optional) * ACC-iQ Models available in these

three sizes only

Vertical Feed (AC Servo) hp 1.07 for ACC-DX Models 1.7 for ACC-iQ Models

Cross Feed (AC Servo) hp N/A for ACC-DX Models 1.7 for ACC-iQ Models

Hydraulic Oil Pump hp 5 7.3 Specifications subject to change without notice.

POWER V 230/460

MODEL Unit ACC-DX Models ACC-iQ Models ACC-DXNC Models

TABLE FEED (Longitudinal)

Hydraulic Feedrate (Average) ft./min. 6 ~ 82 6 ~ 82 10 ~ 82

Hand Feed per Revolution in. 1

COLUMN FEED (Crossfeed)

Manual Infeed

Handfeed per Revolution in. 0.20 0.001 (x1) / 0.01 (x10) / 0.001 (x1) / 0.01 (x10) /

0.1 (x100) / 0.2 (x200) 0.1 (x100)

Handfeed per Graduation in. 0.0008 0.00001 (x1) / 0.0001 (x10) / 0.00001 (x1) / 0.0001 (x10)

0.001 (x100) / 0.002 (x200) 0.001 (x100)

VERTICAL FEED

Manual Downfeed

Handfeed per Revolution in. 0.005 (x1) / 0.05 (x10) 0.001 (x1) / 0.01 (x10) / 0.001 (x0.1) / 0.01 (x1) /

0.1 (x100) 0.100 (x10)

Handfeed per Graduation in. 0.00005 (x1) / 0.0005 (x10) 0.00001 (x1) / 0.0001 (x10) / 0.00001 (x0.1) / 0.0001 (x1) /

0.001 (x100) 0.001 (x10)

Rapid Feedrate in./min. 14 23 79

Auto Infeed

Coarse Grinding in. 0.00005 - 0.0025 0.00001 ~ 0.04 Programmed Through

(Coarse: 15 Steps / Fine: 10 Steps) Conversational Software

Fine Grinding in. 0.00005 - 0.0005 0.00001 ~ 0.04 Programmed Through

(Coarse: 15 Steps / Fine: 10 Steps) Conversational Software

Aircut Amount Coarse Grinding in. N/A Programmed Through Programmed Through

Conversational Software Conversational Software

Aircut Amount Fine Grinding in. N/A Programmed Through Programmed Through

Conversational Software Conversational Software

No. of Sparkouts 0 - 5 0 - 99 0 - 9

14

Page15

ACC-CHiQ SERIES

EXTRA-LARGE HIGH CAPACITY

DOUBLE COLUMN SURFACE GRINDERS

If you’re faced with high-precision surface grinding of extra large components

consider the ACC-CHiQ Series Double Column Grinders.They deliver a new

degree of accuracy and efficiency making them ideal for demanding mold and

die-base production grinding, and other rigorous large component grinding applications.

Check out these value-driven performance features:

n Ultra-rigid, heavy-duty double column ACC-32l80CHiQ Double Column Grinding Machine

design and construction.

n Easy-to-use Okamoto iQ Touch Screen Specifications

Control Table Working Size (W x L): 32" x 80"

n Powerful 30hp spindle motor Max. Distance Under Wheel: 23.5"

n Double-V slideways assure true Table Load Capacity (incl Chuck): 5,512 lbs

tracking and greater table load support Grinding Wheel (D x W x B): 20" x 4" x 8"

n Shift-Plunge Cycle for fast efficient Grinding Wheel Motor: 30 hp / 4P

stock removal Machine Weight: 34,200 lbs

n Multi-level grinding capability

n Available GRIND-BIX High Productivity Other sizes available.

Coolant System enables Contact your Okamoto Grinding Specialist for details.

up to a 10 time increase in vertical

infeed amounts

n Surprisingly small footprint

GRIND-BIX High Productivity

Coolant System

Specifications subject to change without notice

Machine pictured with options

15

Page16

Emerging Abrasives Technology

Okamoto Corporation

370 Corporate Woods Parkway Vernon Hills, IL 60061 USA Tel: (847) 235-3500 Fax: (847) 235-3274

www.okamotocorp.com

PRINTED IN USA 07/16 REV 2